MILESTONES

Read More

2016

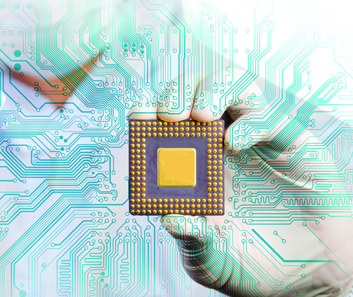

For the past 3 years FASA has taken the strategic step to move away from standardised automation equipment and work on customised equipment with the following characteristics:

- Automated equipment with micro precision production (of up to ± 10-20 microns in size).

- High volume wafer-level packaging systems (where the integrated Circuit is still part of the wafer i.e. true chip-scale package (CSP) technology.

- Complex multi-function automation resulting in fewer steps and lower failure rate of production.

The resulting strategic shift to the above has now made FASA possibly the leading supplier of automated equipment for one of the leading micro-optics systems company using wafer level optic technology to produce the optic component used in the latest Smart Phone Technology.

FASA has also successfully penetrated the following key industries where wafer level packaging systems require complex and high precision manufacturing systems.

- Solid State Drive (SSD) market

- Smartphone components

- Automotive

- Medical Devices

2016

Read More

2013

Continuously achieve new technological breakthroughs and innovations to provide better systems and solutions to customers while cutting down costs.

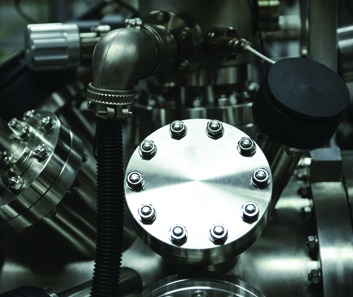

Created new High-speed/ High Precision fully automatic equipments and solutions for various applications including Test handlers, Testing and Packaging, Assembly, Inspection, Laser Marking including Vision Inspection, Laser Welding, Labeling, Chiller Systems, Curing Systems, Die Inspection and Sorting Systems and many others systems for Semiconductor, Electronics, Automotive, Hard Disk / Media, G6/ G7/ G8 LCD Glass Inspection and others.

Conceived, developed, designed, and successfully realized the next-generation Wire-Saw Equipment, which is used in the Solar Industry for slicing of ingots into wafers. The result is a brand new system that can slice silicon ingots into ultra-thin wafers so as to significantly reduce the total cost of solar photovoltaic (PV) panel manufacturing.

2013

2009

Read More

2004

Successfully developed and commissioned a series of equipments for hard-disk media industry after successfully achieving compliance to Clean Room Class 10 and stringent SOP 39 standards. This marked a quantum leap in achieving several ingenious innovations in engineering applications within a very short lead-time. This period demonstrated the successful coming to bear of the accumulated engineering acumen and judgment of FA design teams in the successful realization of these key projects for our renowned fortune-500 customer.

2004

2002

Read More

2001

FA Systems focused on manufacturing of equipments for the Photonics, Semiconductors, Electronics and Medical Industries. Built standard machines for Laser Marking System and Singulation Saw for the SEMICON industries. Successfully launch of the Advanced Packages Singulation Saw, which was exhibited at the SEMICON Singapore trade show in 2001.

2001

Read More

2000

The business of FA Systems is further boosted with funding from new investors with market networking. Additional headcount, machinery and factory space were added to cope with surge in customer demand. FA Systems acquired a stake in Laser Research, a NUS-Data Storage Institute (DSI) spin-off with core competency in laser applications. This acquisition provided gives FA Systems the additional competitive advantage in its automation manufacturing systems capabilities. Also successfully designed and manufactured large, high-precision equipments complying with the European CE mark standard for export to EU nations.

2000

Read More

1996

FA Systems expanded its facility by moving to its present location in order to better service its expanding customer base. Contract manufacturing services, including mass production of precision small components and subassembly processes, were added to its business activities.

1996

Read More

1993

FA Systems began providing a full range of automation solutions for multinational companies (MNCs). Sophisticated machinery like the CNC machining center was also acquired to facilitate the making of more precise and complicated machine parts.

1993

Read More

1989

The partnership expanded and strengthened its business by providing in-house machining services. FA Systems incorporated itself as a private limited company and moved to a 300 square meters factory with six milling machines and ten staffs.