FASA – Your Manufacturing Partner

With 35 years of industry experience, we have built a reputation for excellence, reliability, and customer satisfaction. Our state-of-the-art facilities, advanced technologies, and skilled team enable us to deliver top-notch products across various industries. From concept to completion, we collaborate closely with our clients, understanding their unique needs and translating them into innovative and cost-effective manufacturing solutions. With a strong focus on quality, precision, and timely delivery, we strive to exceed expectations and foster long-term partnerships with our clients. We aim to be at the forefront of the manufacturing industry, continually adapting and expanding our capabilities to meet the evolving needs of our clients and the market as a whole.

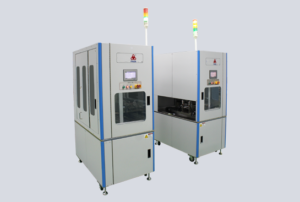

FEATURED MACHINES

Over the decades, FASA has become an advanced solutions provider specializing in customized equipment while developing standard systems.

PRODUCTS AND SOLUTIONS

We are extremely proud to offer full turnkey manufacturing systems and solutions, perfect for all industries and sectors.

LATEST NEWS

Read all the latest industrial news and views from professionals in the automation sector.